Plastics for building drainage

1950: PE pioneers

First drain assemblies, later entire piping systems: Geberit is a pioneer in establishing the plastic polyethylene (PE) in the sanitary industry in the mid-1950s. A look back on the occasion of Geberit's 150th anniversary.

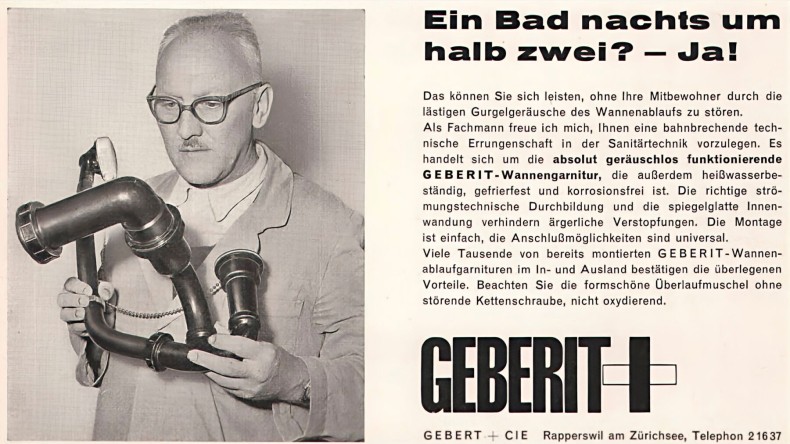

They are pitch black and not the usual cast iron, copper or fibre cement. We are talking about a range of fittings and pipes that Geberit launched on the market in 1966.

PE - an ideal material

It is polyethylene (PE), a plastic from which Geberit has been manufacturing traps and drains for ten years. PE is an ideal material for sanitary applications: It is resistant to almost all chemicals, can withstand hot water and frost, is impact-resistant and corrosion-resistant. It is also very easy to process.

In the 1960s, PE opened up a wide range of applications in drainage, from residential buildings to sophisticated laboratory installations. Nevertheless, the introduction of PE as a relatively new material remains a risky endeavour: both tradesmen and engineers have reservations; they generally consider plastics to be inferior.

Waste water experts

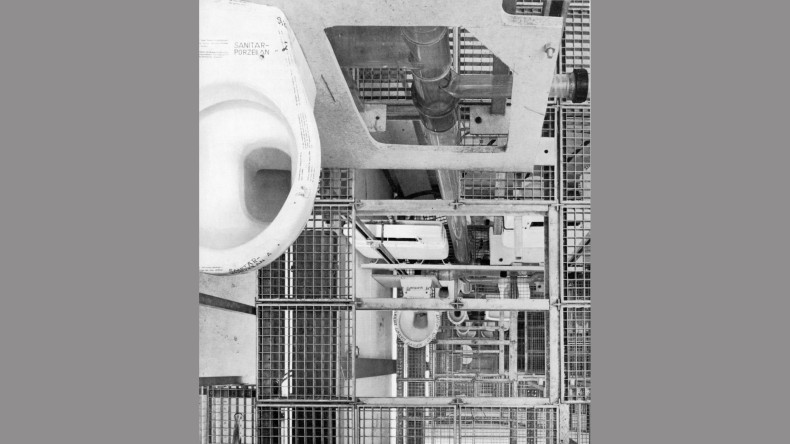

Geberit is pioneering in the field of wastewater management. In the 1960s, engineers and hydraulic specialists in Jona conducted fundamental research in the previously underexplored area of building drainage systems. They examined the water and air circulation in pipes and optimised their efficiency. For this purpose, they had access to a seven-storey experimental wastewater facility, of which there were only a few in Europe.

Training campaign and market penetration

Technical expertise alone is not enough to conquer the market. In hundreds of training courses in Europe, Geberit demonstrates the robustness and versatility of PE products as well as how to process the material. In its own training centres, later known as Geberit Information Centres (GIZ), Geberit sets up transparent wastewater systems and demonstrates comparative installations. The training campaign pays off: Sanitary professionals recognise the installation advantages of PE. By the end of the 1980s, PE pipes had replaced traditional materials in many countries.

Continuous optimisation

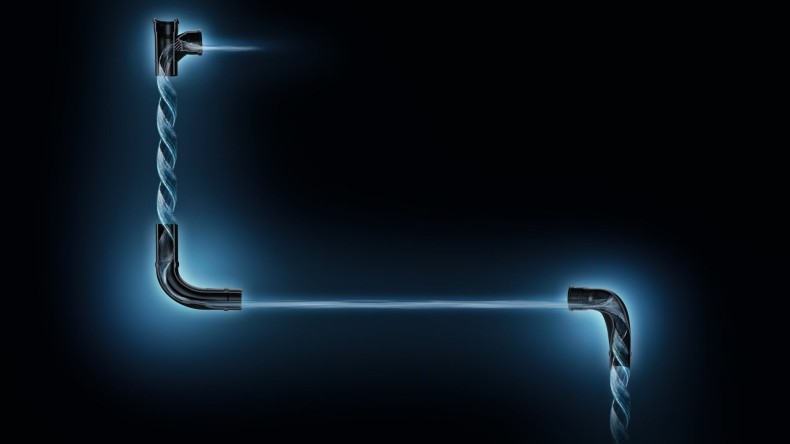

Geberit continuously optimises the hydraulics of waste water systems. In the early 1970s, Sovent, a pioneering product that makes wastewater downpipes in high-rise buildings more efficient, is launched on the market. In 2019, Geberit further develops Sovent into the SuperTube system, which completely eliminates the need for ventilation pipes. Geberit's expertise in hydraulics and building acoustics will come together in 2024 in Silent-Pro SuperTube for low-rise buildings.

150 years of Geberit: A look into the past

We are celebrating the anniversary with several articles and are therefore publishing historical stories from the company archive throughout the current year.

Further exciting information can be found on the anniversary website www.geberit150.com